An engine made for renewable fuels

Three research teams from ETH Zurich and Empa have joined forces in an interdisciplinary project to investigate how internal combustion engines can be made fit to use of renewable, CO2-neutral fuels. In addition to electromobility, fuels from biogenic sources ('biofuels') or 'e-fuels' produced synthetically with regenerative electricity can also contribute to sustainable mobility.

Because of competition from food production, critics strictly reject biofuels. Proponents, on the other hand, see biofuels as an important approach to replacing fossil fuels and as a step towards CO2-neutral mobility. Proponents claim that biofuels can also be produced without the use of food plants. This is the case, for example, when sewage sludge or agricultural waste is fermented into biogas and then refined into biomethane. Or if a synthetic fuel such as OME is used, which can be produced from CO2, water and renewable electricity, for example, or regeneratively produced methane. With such fuels, proponents hope, the vision of a CO2-neutral combustion engine could become reality.

Relaxed cooperation between three research institutes

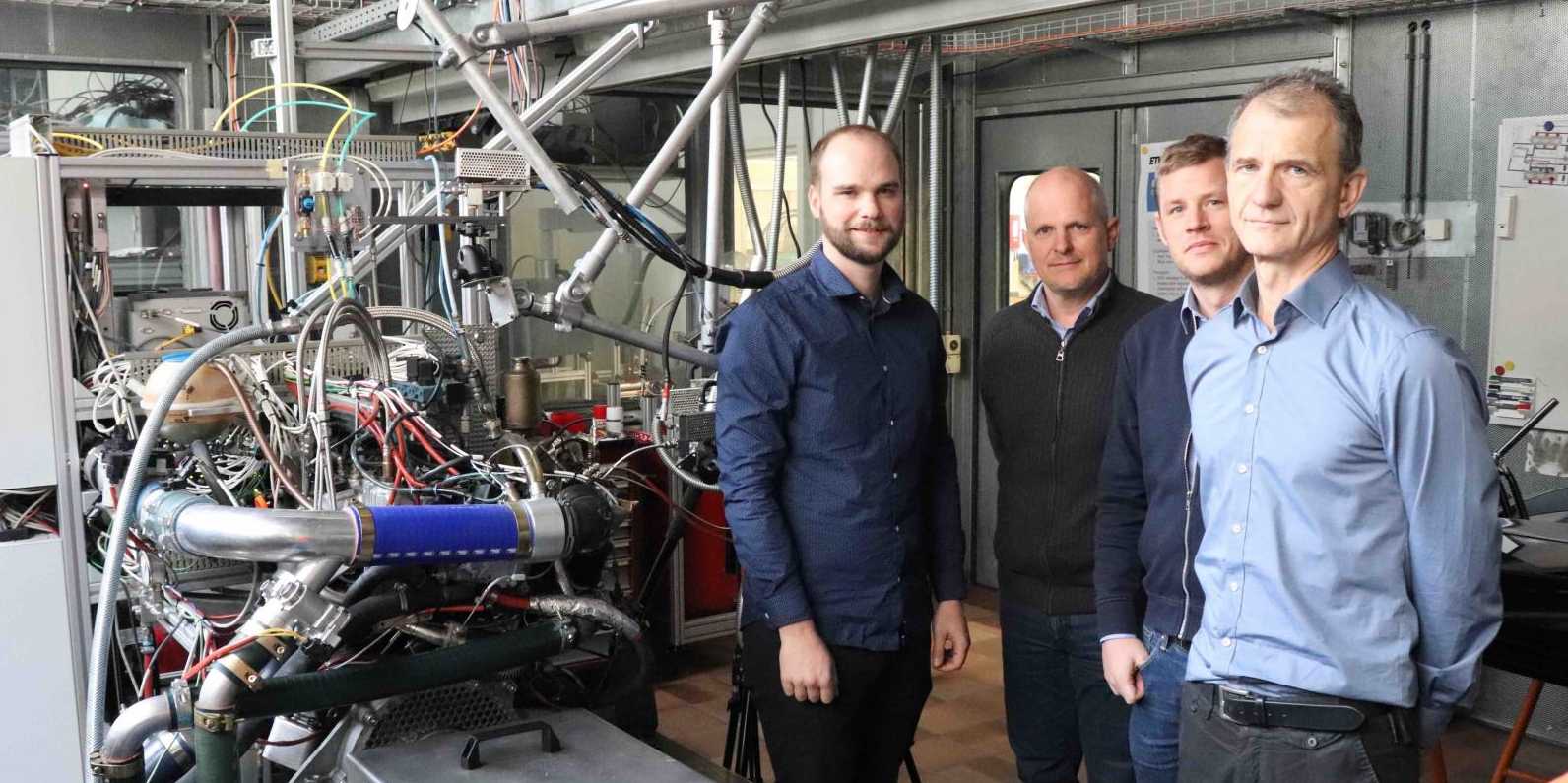

Against this background, scientists from ETH Zurich and the Swiss Federal Laboratories for Materials Testing and Research Empa in Dübendorf (ZH) carried out the NextICE project from 2014 to 2018. The focus was on the question of what a future internal combustion engine (ICE) should look like that is designed to operate on renewable fuels. “Combustion engines have so far been optimized for fossil fuels such as gasoline and diesel. If we want to operate them with renewable fuels in the future, we have to redesign the combustion engine - this applies not only to the combustion processes and control techniques used, but also to the mechanical design of the engine,” says Prof. Christopher Onder, ETH Professor and head of the NextICE project.

Onder then highlights the three central questions that were worked on by each research team within the framework of the project: The ETH Laboratory for Aerothermochemistry and Combustion Systems (LAV/Prof. Konstantinos Boulouchos) was dedicated to the new combustion processes; the ETH Institute for Dynamic Systems and Control (IDSC/Prof. Christopher Onder) to control technology, while the Empa Vehicle Propulsion Systems Department (Christian Bach) was responsible for engine design issues. In each of the three subprojects, the three partners worked on their own questions, but communicated and interacted to establish important links. “This relaxed cooperation was very helpful and has brought us forward,” says Christopher Onder.

OME motor enables compact catalytic converter

In their subproject, the LAV researchers studied the combustion of OME fuel in an insulated combustion chamber and a special single-cylinder experimental diesel engine. For their study, they used pure OME as fuel as well as OME mixed with diesel fuel. A key result: the combustion of pure OME produces practically no soot. The big advantage is that exhaust aftertreatment can be greatly simplified when using OME compared to diesel: under current legislation, a fine particulate filter can be dispensed with, as can an SCR system for reducing nitrogen oxides. These, together with CO and unburned hydrocarbons, can then be removed in a compact 3-way catalytic converter.

The scientists around Prof. Onder approached the problem of a new combustion engine from the control engineering side. Among other things, they wanted to know what the optimal operating strategy is for an engine powered by biofuels or sustainable synthetic fuels. The operation of a passenger car is very dynamic and the engine must therefore be able to change speed and torque quickly. “An engine works at different operating points and has to master the transitions between them well; this is a great challenge, especially for fuels that are similar to petrol and therefore difficult to ignite, such as methane, ethanol and methanol,” says Richard Hutter, the main researcher in Prof. Onder’s research group. Hutter has written his doctoral thesis as part of this project.

Optimum methane engine operation

Richard Hutter focused his investigation on methane. Methane is the main component of natural gas, but can also be produced from biogenic sources - such as biogas - or synthetically using renewable electricity. Methane is already used today as a fuel in cars powered by a gasoline engine that has been converted to run on natural gas. Richard Hutter went one step further in his study: he used methane in a modified diesel engine: In the so-called dual fuel engine, the self-igniting diesel is used to ignite the difficult to ignite methane. In his study, the ETH researcher was able to demonstrate a decisive advantage of this concept: “With the dual fuel-engine, we were able to increase the efficiency of the methane-powered engine by 5 percentage points to 42%, i.e. we achieved the efficiency of a diesel engine with methane, a fuel that is similar to gasoline,” Hutter summarizes one of the main results of his study.

Author: Dr. Benedikt Vogel, on behalf of the Swiss Federal Office of Energy (SFOE)